A Comprehensive Overview to Galvo Motors and Their Influence On Laser Equipments

Galvo electric motors have actually arised as an essential part in the evolution of laser systems, giving improved precision and efficiency throughout numerous applications. What might this mean for the landscape of laser technology?

What Are Galvo Motors?

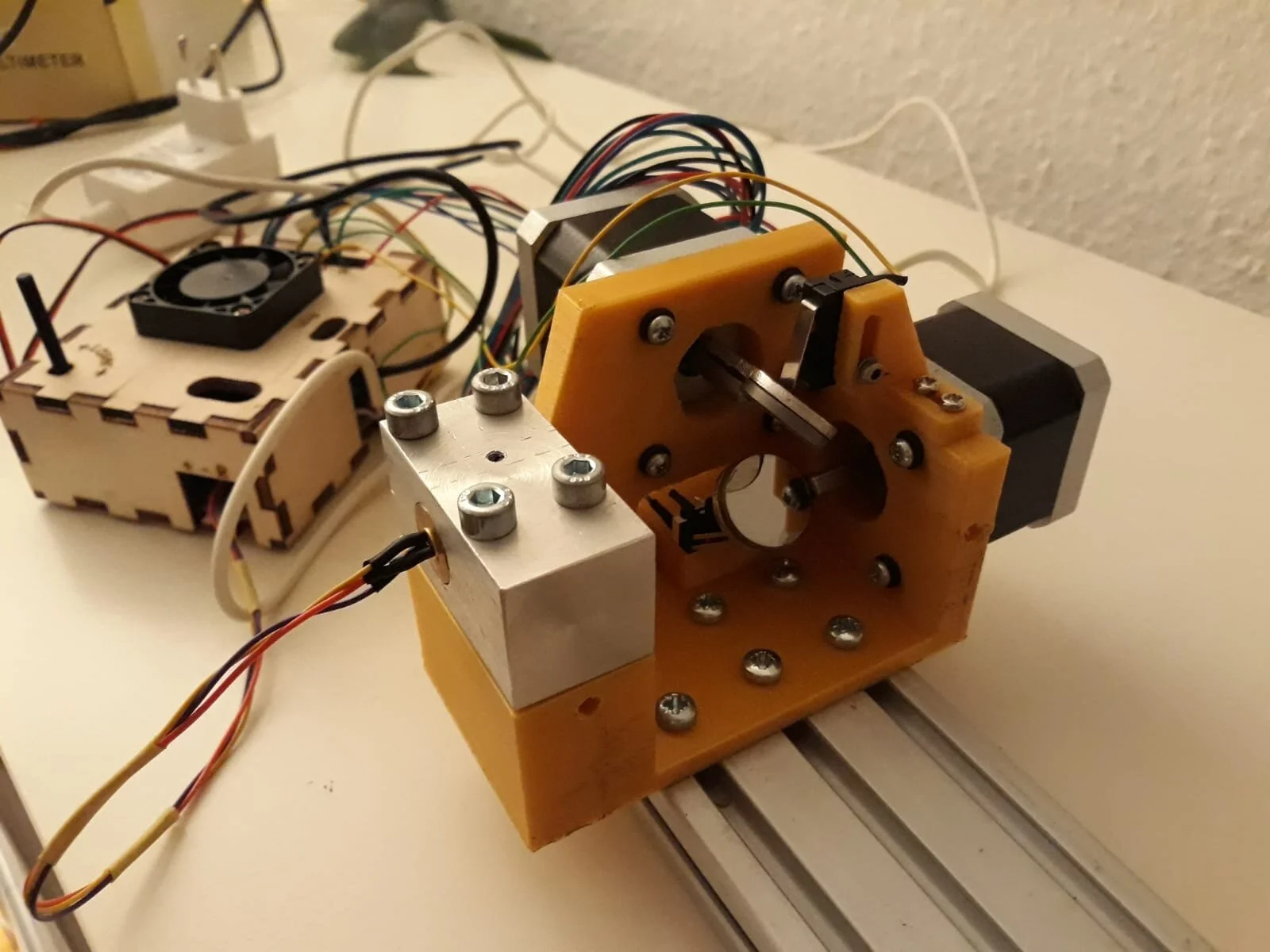

Galvo motors, short for galvanometer electric motors, are precision tools utilized to regulate the setting of mirrors or lenses in laser systems. These electric motors are important to different applications, including laser engraving, reducing, and estimate systems, where accurate placing is vital for optimum performance. Galvo electric motors use a light-weight layout that allows quick motion, permitting high-speed procedure and specific control of laser beam of lights.

Additionally, galvo electric motors can be integrated with advanced control systems, enabling sophisticated programs and automation. This adaptability not just boosts operational effectiveness yet likewise ensures consistency in output. As an outcome, galvo motors have actually come to be an essential element in modern-day laser innovation, helping with advancements in various fields by allowing precise control of light with extraordinary speed and accuracy.

Just How Galvo Motors Operate

The procedure of galvo electric motors relies on accurate electromagnetic systems that assist in fast and accurate positioning of mirrors or lenses. At the core of a galvo electric motor system are rotary coils installed on a shaft, which communicate with magnetic fields created by permanent magnets.

Galvo motors are defined by their closed-loop control systems, which utilize responses from placement sensors to ensure precision. These sensing units keep an eye on the angular position of the mirrors, passing on data to the controller that adjusts the existing supplied to the motor. This responses loophole permits for fine-tuning of the motor's placement, causing high repeatability and accuracy.

Additionally, the lightweight building of galvo electric motors decreases inertia, making it possible for quick feedback times important for laser scanning applications. Overall, the mix of electromagnetic principles and closed-loop comments systems allows galvo motors to perform complex jobs with remarkable accuracy and rate, making them important in innovative laser modern technologies.

Benefits of Galvo Motors

One of the vital advantages of utilizing galvo motors in laser systems is their capacity to accomplish quick and accurate positioning, which is vital for applications such as laser engraving, cutting, and scanning. This accuracy is mainly due to the high-speed action of galvo motors, enabling them to swiftly adjust the angle of the laser beam of light with very little delay.

Another considerable benefit is their minimized inertia contrasted to standard stepper electric motors, which permits quicker velocity and deceleration. This particular not just enhances the general rate of laser procedures yet additionally contributes to the quality of the completed product by lessening motion blur.

Applications in Laser Systems

Applications of galvo electric motors in laser systems cover a wide variety of sectors, showcasing their flexibility and performance. Largely used in laser etching and noting, galvo motors allow specific control over the laser light beam's placement, helping with elaborate layouts on different products such as steels, plastics, and glass. Their fast action times and accuracy significantly improve manufacturing performance, making them important in manufacturing procedures.

In the realm of laser cutting, galvo electric motors enable high-speed procedures, decreasing the read here time required for complex cuts while maintaining edge high quality. This capacity is specifically beneficial in industries like automotive and aerospace, where accuracy is critical. Galvo motors are important in laser scanning applications, such as in 3D laser scanning and imaging systems, where they assist in fast data purchase and analysis.

Clinical applications also take advantage of galvo innovation, particularly in laser surgical procedure and diagnostic tools, where precise beam of light control is vital for efficient outcomes. Additionally, the introduction of laser-based micro-machining processes has actually seen the fostering of galvo electric motors, boosting the ability to carry out fragile operations with unparalleled accuracy. Generally, galvo electric motors play a critical role ahead of time laser innovation across varied fields.

Future Patterns in Galvo Modern Technology

Increasingly, innovations in galvo innovation are positioned to revolutionize numerous sectors that depend on laser systems. One considerable pattern is the integration of fabricated knowledge (AI) and artificial intelligence algorithms into galvo control systems. These innovations improve accuracy and adaptability, enabling real-time adjustments based upon dynamic environmental problems or product residential properties.

An additional emerging fad is the advancement of higher-speed galvo motors, which facilitate faster click resources processing times in applications such as laser inscription and cutting - Galvo Scanner. As markets demand quicker turn-around times, these developments will end up being important for keeping competitive advantage

Furthermore, miniaturization of galvo parts is making laser systems extra versatile and portable. This pattern is especially relevant in industries such as clinical tools, where space restraints are vital.

Final Thought

Galvo electric motors have actually emerged as a crucial element in the evolution of laser systems, providing enhanced accuracy and effectiveness across different applications.Galvo motors, brief for galvanometer motors, are accuracy devices utilized to regulate the setting of mirrors or lenses in laser systems. Primarily utilized in laser inscribing and noting, galvo motors allow precise control over the laser beam of light's position, facilitating complex designs on various materials such as steels, plastics, and glass. Galvo electric motors are critical in laser scanning applications, such as in 3D laser scanning and imaging systems, where they assist in quick data purchase and analysis.

As improvements in closed-loop control systems and artificial intelligence integration proceed to evolve, the capacity for galvo motors to additionally change see this page laser systems stays considerable, encouraging enhanced speed and reduced activity blur, consequently expanding their energy across diverse industrial industries.